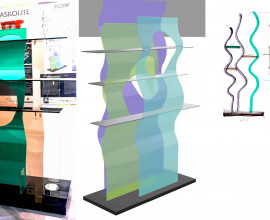

From textile flooring for the exhibition channel to retail design, the Brescia-based company is expanding its range of products and services in anticipation of new markets.Montecolino is going to unveil several new products: a new recycled sheet material, and with acquisition of Topcolor, a company specializing in printing for the retail world. Firsth, in an upcycling operation, in the wake of the sustainability that has always been its hallmark, Montecolino has developed Wèp (Wall Eco Pannel), a polypropylene panel produced by recycling exhausted carpet from trade shows. “We have also come up with a slogan that says: Wèp is the first panel with an emphasis on ecology!” explains Nico Fontana, CEO of Montecolino. Since the end of 2022 it is being offered as support for display design, shopfitting and visual merchandising projects for the store-marketing and exhibition world. At the end of its life Wèp is itself recyclable into a new panel, and with each step the percentage of carbon footprint saving increases. “At the company level we manage to recycle 25 percent of the carpets,” Fontana says, “The increase in this percentage depends, of course, on the availability of customers. For example, in 2021 Fiera Milano, with Montecolino, determined that about 86 percent of the carpeting used in its exhibition events would be recycled. And in 2022 the official figure will approach 100 percent.” Since December 2018 Wèp has been certified “Recyclable Plastic” by IMQ (Italian Institute of Quality Mark).

The importance of the environment is also high on the agenda in the world of printing, and Topcolor works with water-based UV inks and eco-friendly materials, with 100% polyester increasingly in demand.

The possibilities of flatbed (flat) large-format roll-to-roll printing reach up to 5 m, with almost endless options regarding the use of materials, the key is to respect the flatness of the surfaces to be printed on (up to a maximum of 3.5 cm thick). The company is also up to date on the 3D printing angle.

On one hand with additive printing processes that allow the realization of PLA products, for high-definition projects (with Ultimaker machines for sizes up to 30 cm3, or with Builerd printer for productions up to 70x70x170 cm).

On the other, with subtractive printing, through KUKA, a seven-axis robot that carves polystyrene (up to 2.5 m high single piece), a material that can then be sprayed with a two-component material (polyurea) that makes it shockproof and waterproof and suitable for outdoor uses, as well as fiberglass adjusting to a complex and multifaceted field of action ranging from window dressing to playgrounds.

“This is a new field, which does not only entails printing, but also involves designers and decorators, yet it is bringing us great satisfaction,” says Luca Rossi, Executive Director of Topcolor. At 60 percent, the company’s core business still remains printing, between flat and roll-to-roll, but the demand for 3D mockups is increasing by the day.

With regarding channel of use of Topcolor technologies are certainly interesting sector as temporary replacement of works on loan or in churches where the works have been stolen: through special craclè varnishes, the final output is very faithful to the originals.

One of the first projects, following the acquisition by Montecolino, involves the purchase of a printing press with 3.20 m of light for sublimation printing, thus adding to the Latex and UVI presses already present in the Topcolor arsenal.

About their acquisition by Montecolino, Rossi explains, “What we share in common is the range of our offerings. Alongside our divisions there are others that complement and enrich our skills,” carpenters, artists, and professionals from different fields. With this structure, the company is able to create customized projects, even one-of-a-kind works, with the most complex, custom-designed techniques, as in the case of printing on canvas for the recreation of paintings – to be placed in museums.

About their acquisition by Montecolino, Rossi explains, “What we share in common is the range of our offerings. Alongside our divisions there are others that complement and enrich our skills,” carpenters, artists, and professionals from different fields. With this structure, the company is able to create customized projects, even one-of-a-kind works, with the most complex, custom-designed techniques, as in the case of printing on canvas for the recreation of paintings – to be placed in museums.

company focused on the trade fair world, a sector that, according to UFI (World Association of the Trade Fair Industry) data, has grown annually by 6 percent over the past decade (not counting the pandemic period shutdown). The Brescia-based company over the years has often worked for high-profile international clients such as Roland-Garros, the Tour de France and the Motomondiale, as well as runway shows of major fashion brands; Italian clients since 2017 include the Fiera di Milano (production, installation and disposal). More than 300 items including carpets (both needlepunched and woven), rugs, synthetic grasses, upholstery and textiles are featured in Montecolino’s catalog. Not merely products, however: over the years additional services such as print work for customized designs and, since 2017, that of installation, material recovery and recycling have been added to their range of services offered to customers. Ample space is given to products in their “eco” series, which are certified as 100% recyclable (certification was issued by the authorized laboratories of CSI, a Certification and Analysis Center that operates internationally in the business services sector). Special attention is paid to the ultimate destination of textile waste, which is returned to the production cycle, and residues, which are separated according to composition and destined for recovery outside the company

company focused on the trade fair world, a sector that, according to UFI (World Association of the Trade Fair Industry) data, has grown annually by 6 percent over the past decade (not counting the pandemic period shutdown). The Brescia-based company over the years has often worked for high-profile international clients such as Roland-Garros, the Tour de France and the Motomondiale, as well as runway shows of major fashion brands; Italian clients since 2017 include the Fiera di Milano (production, installation and disposal). More than 300 items including carpets (both needlepunched and woven), rugs, synthetic grasses, upholstery and textiles are featured in Montecolino’s catalog. Not merely products, however: over the years additional services such as print work for customized designs and, since 2017, that of installation, material recovery and recycling have been added to their range of services offered to customers. Ample space is given to products in their “eco” series, which are certified as 100% recyclable (certification was issued by the authorized laboratories of CSI, a Certification and Analysis Center that operates internationally in the business services sector). Special attention is paid to the ultimate destination of textile waste, which is returned to the production cycle, and residues, which are separated according to composition and destined for recovery outside the company